DCI®

Corrosion Inhibitor ASTM C494 Type C

Product Description

DCI® Corrosion Inhibitor is a liquid added to concrete during the batching process. It chemically inhibits the corrosive action of chlorides on reinforcing steel and pre-stressed strands in concrete. It also promotes strength development of the concrete while meeting ASTM C494 requirements as a Type C admixture.

One gallon of DCI weighs approximately 10.7 lbs (one litre of DCI weighs approximately 1.28 kg ± 0.01 kg). DCI contains a minimum of 30% calcium nitrite.

Uses

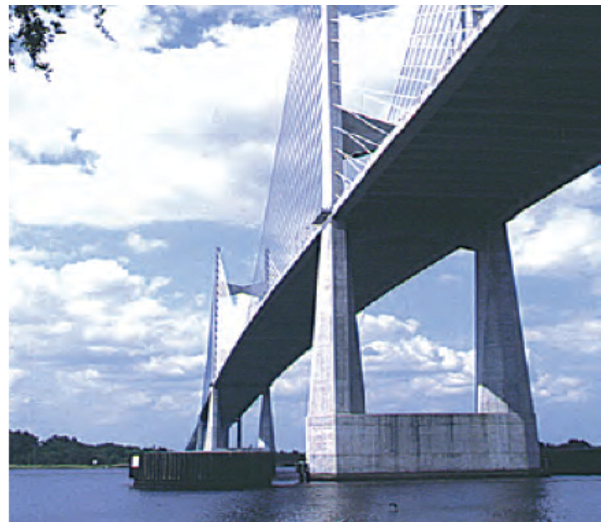

DCI is recommended for all steel-reinforced, post-tensioned and pre-stressed concrete that will come in contact with chlorides from de-icing salts or a marine environment. Examples are parking garage decks and support structures, bridges decks and pre-stressed members, and structures in marine environments. It may also be used in concrete where chlorides are added during manufacture.

Advantages

- Chemically inhibits the corrosive action of chlorides on reinforcing steel and pre-stressed strands in concrete.

- Extends the service life of structures in a de-icing salt and marine environment.

- Cost-effective solution to the control of reinforcing steel chloride-induced corrosion.

- Accelerates the set of concrete, which would allow DCI to be used as a concrete set accelerator.

Preconstruction Trial Mix

It is strongly recommended that trial mixes be made several weeks before construction start up. This will allow the concrete producer an opportunity to determine the proper batching sequence and amounts of other admixtures needed in order to deliver the required concrete mix to the job site. Due to the cement response variation and the strong acceleration potential of DCI, it is vital that set time and slump retention of the proposed mix be thoroughly tested and evaluated in the light of job requirements. GCP Applied Technologies’ broad experience with this product can help the concrete producer deliver satisfactory product regardless of the mixture proportions. Contact your GCP admixture representative for help with trial mixes.

Air Entrainment

DCI Corrosion Inhibitor at the normal addition rates may moderately reduce the entrained air content. It may be necessary to increase the dosage of the air-entraining admixture to compensate. Project specifications of DCI generally will show requirements of 6 ½ ± 1 ½% air in the plastic or fresh concrete.

Finishing and Curing

Concrete containing DCI Corrosion Inhibitor finishes with standard tools and techniques. It is no different from any other air-entrained, low w/c ratio mix in terms of finishability. Curing procedures must follow ACI 302 and ACI 308.

Performance

DCI Corrosion Inhibitor contains calcium nitrite which interacts with the embedded steel in concrete to prevent salt attack. By chemically reacting with the reinforcing, a barrier is formed which prevents chloride penetration. Corrosion initiation is delayed and corrosion rates are kept under control. Once corrosion has been inhibited, physical disruption of the concrete due to rust formation will not occur.

When added to concrete in sufficient quantity as determined by the anticipated chloride ion content of the concrete over the design life of the structure, DCI maintains an active corrosioncontrolling system within the concrete matrix.

Set Acceleration

At all recommended addition rates, DCI® Corrosion Inhibitor may accelerate concrete setting times, which may also aggravate slump loss. To extend the set time to a more normal duration, separately add a retarder such as DARATARD® 17 or DARATARD® HC. A retarder may not be necessary in cold weather. The full accelerating action of DCI may actually be desirable during the cool months of the year.

Addition Rates

Recommended addition rates range from 2.0 to 6.0 gal/yd3 (10 to 30 L/m3). The level of corrosion protection increases in proportion to the dosage. The project specification will indicate the addition rate. In the absence of a specified dosage, or where needed to offset premixed chlorides, call your GCP admixture technical representative.

DCI also increases the early strength of a concrete mixture and may have an accelerating action on setting time. These effects become more pronounced as the addition rate rises. Control of setting time can be achieved with retarding admixtures (see Set Acceleration).

Mix Water Reduction

Mix water adjustment is essential to account for the water in DCI and thus maintain the desired w/c ratio. The mix water added at the batch plant must therefore be reduced to compensate for the addition of the corrosion inhibitor. The adjustment factor is 7.0 lbs per gallon of water (.84 kg/L) of DCI.

A high-range water reducer such as ADVA®, DARACEM® 100 or DARACEM® 19 may be used to maintain workability in low w/c ratio concrete.

Compatibility with other Admixtures and Batch Sequencing

DCI is compatible with most GCP admixtures as long as they are added separately to the concrete mix, usually through the water holding tank discharge line.

In general, it is recommended that DCI be added to the concrete mix near the end of the batch sequence for optimum performance. Different sequencing may be used if local testing shows better performance.

Please see GCP Technical Bulletin TB-0110, Admixture Dispenser Discharge Line Location and Sequencing for Concrete Batching Operations for further recommendations. DCI should not come in contact with any other admixture before or during the batching process, even if diluted in mix water.

DCI is also classified as an ASTM C494 Type C set accelerator. As such, it may be used to accelerate the set time of concrete. If a neutral set is required, the addition of an ASTM Type B or D set retarder may be added to the concrete mix.

Pretesting of the concrete mix should be performed before use, and as conditions and materials change in order to assure compatibility, and to optimize dosage rates, addition times in the batch sequencing and concrete performance. For concrete that requires air entrainment, the use of an ASTM C260 airentraining agent (such as DARAVAIR® or DAREX® product lines) is recommended to provide suitable air void parameters for freezethaw resistance. Please consult your GCP representative for guidance.

Cement Compatibility

DCI Corrosion Inhibitor is compatible with all types of Portland cement, and concretes containing pozzolans. However, due to the significant variation between cements, even the same type, may result in differences in cement response to DCI. This is especially true with respect to the effect on setting time, which also influences slump retention.

Packaging & Handling

DCI Corrosion Inhibitor is available in bulk quantities from GCP metered systems or in 55 gallon (208 litre) drums.

Dispensing Equipment

A complete line of accurate dispensers is available. DCI may be introduced on the sand, in the water, at the beginning or the end of the batch cycle. Similar to all concrete admixtures, DCI should not come into contact with other admixtures prior to entering the concrete.

Freezing Point

DCI freezes at approximately 5 °F (-15 °C), but its corrosion inhibition and strength gain properties are completely restored by thawing and through agitation.

Technical Service

The Technical Service Department of GCP is available to assist you in the correct and best use of our products. These resources and advice are at your disposal entirely without obligation. Please contact:

GCP

Emirates Chemicals LLC

Festival Tower, Suite 1701

Dubai Festival City

P.O. Box 5006

Dubai, United Arab Emirates

Tel: +971 4 2329901

Fax: +971 4 2329940

Email: meinfo@grace.com

gcpat.vn | For technical information: asia.enq@gcpat.com

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

DBM is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2017 GCP Applied Technologies Inc. All rights reserved.

GCP0082-1216 DCI-UAE

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

GCP Vietnam Company Ltd, Lot B14, Section B, Street No. 12, Xuan Thoi Son Small Scale Arts & Crafts Group, National Road 22Xuan Thoi Son Village, Hoc Mon District, Ho Chi Minh City

This document is only current as of the last updated date stated below and is valid only for use in Vietnam. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.vn. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2022-10-13

https://gcpat.vn/en-gb/solutions/products/dci-corrosion-inhibitor/dci